Equipment according to your needs

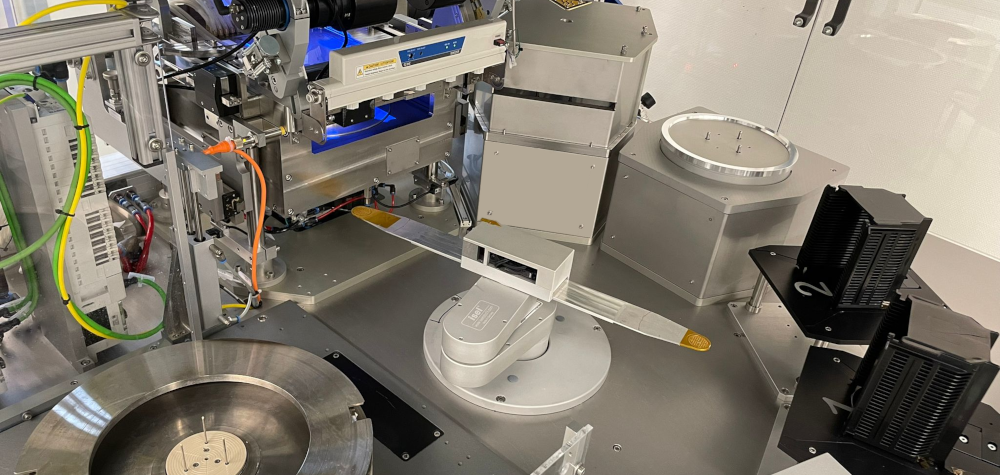

FabSCIL:

From manual R&D to fully automatic

FabSCIL family allows printing of 150 to 300 mm wafers with automatic loading and positioning of the stamp.

FabSCIL is designed to be connected to a cluster system that operates wafer handling, spin-coating, baking, cooling, and other processes.

Doing up to 80 wafers per hour with an overlay accuracy of sub-1µm, our FabSCIL cluster is suitable for high-volume production manufacturers. The modular platform can be customized with additional tools: multiple FabSCIL modules, spin coaters, etc. to fit your requirements.

20-80

wafers/h

< 1μm

alignment accuracy

150 – 300 mm

wafer size

AutoSCIL: Integrated Tool

AutoSCIL makes easy to perform nanoimprint production with real-time process monitoring.

With all the necessary processes to obtain the nanopatterns included: wafer handling, aligning, spin-coating, SCIL imprinting and baking and cooling. The compact tool you are looking for.

30-60

wafers/h

< 1μm

alignment accuracy

100 – 200 mm

wafer size

LabSCIL: Specially developed for R&D

LabSCIL is perfect for new product development.

Ideal for universities, research centers, or laboratories, the LabSCIL uses the same automatic imprint technology as the high-volume SCIL tools but with the manual loading of wafers.

Semi-automatic

< 1 μm

alignment accuracy

100 – 200 mm

wafer size